Innovative Partnership Aims to Future Proof Artificial Turf Pitch Maintenance

Across Europe, regulatory change is reshaping the artificial turf landscape.

With EU legislation set to phase out traditional SBR rubber crumb infill, derived from end-of-life tyres, on 3G artificial grass pitches by 2031, the industry is preparing for transition. While it remains uncertain whether identical legislation will be adopted in the UK, market direction is already shifting.

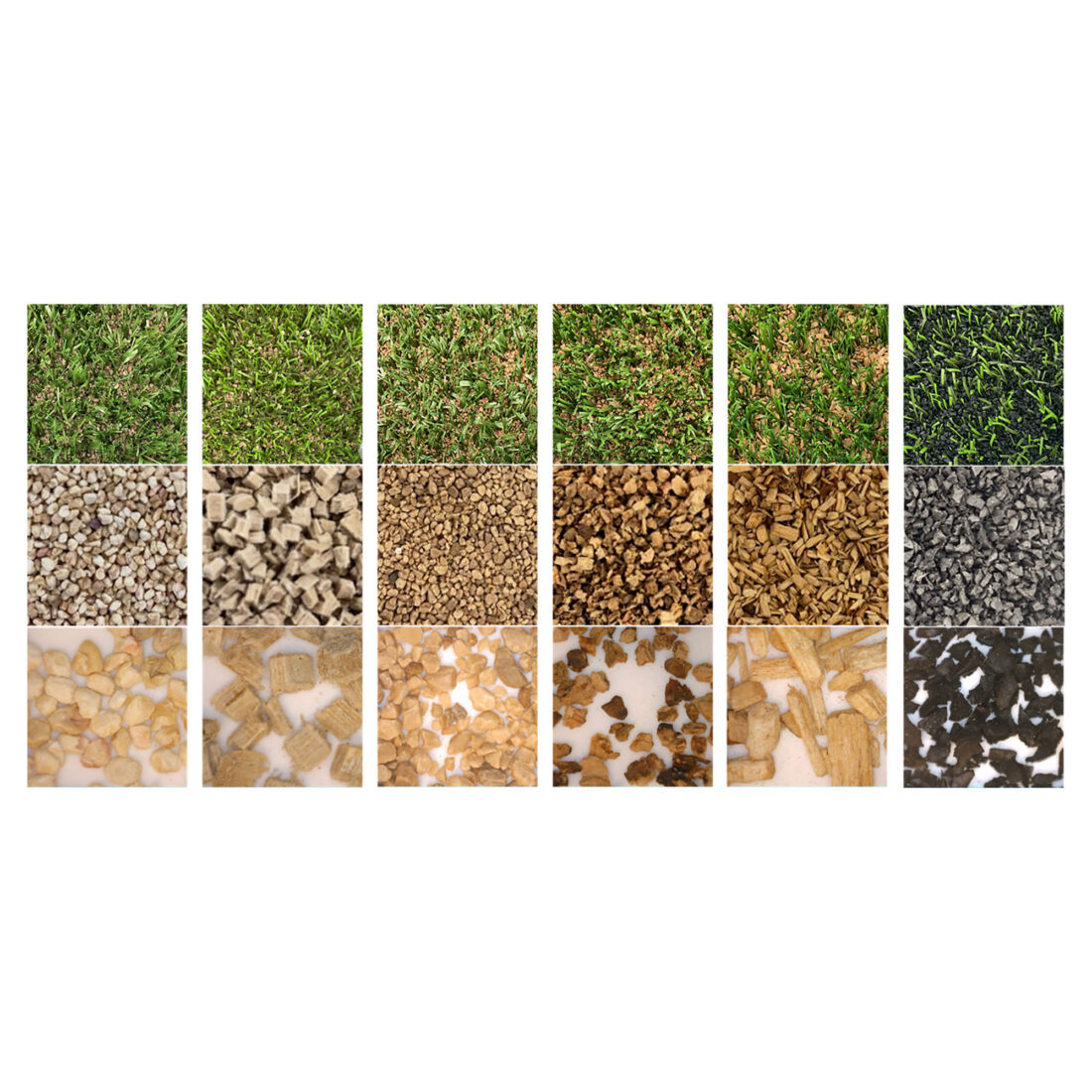

An increasing number of new installations now specify non-SBR alternatives, including cork, pine, birch wood, olive pits and corn-based materials. Sustainability considerations, perception, and future-proofing strategies are influencing procurement decisions across schools, universities, local authorities and professional facilities.

However, innovation in materials inevitably introduces new technical questions.

A Changing Material Landscape

Traditional rubber crumb infill systems have been installed and studied for decades. Their mechanical behaviour, durability characteristics and maintenance response are relatively well understood.

Organic infill systems are different.

They exhibit:

- Greater variability in particle shape and density

- Increased moisture absorption

- with a greater sensitivity to frost and freezing conditions

- Potential physical degradation

- Different compaction behaviours

For facility operators, these differences carry implications for:

- Player safety

- Surface consistency

- Maintenance frequency

- Lifecycle cost forecasting

- Long-term asset protection

At present, the long-term performance behaviour of many organic infill materials under UK climatic and usage conditions is not yet fully demonstrated.

A New Knowledge Transfer Partnership

To address these uncertainties, Technical Surfaces has launched a new Knowledge Transfer Partnership (KTP) with academic experts from the Sport Surfaces Research Group within the Sports Technology Institute.

KTPs are collaborative innovation programmes part-funded by Innovate UK. They unite industry and academia to solve strategic technical challenges through structured research.

This 30-month project is led by KTP Associate Zach Morley (Sport Pitch Performance Engineer, Technical Surfaces), and focuses on developing evidence-based maintenance and performance monitoring frameworks for next-generation organic infilled artificial grass pitches.

The objective is clear: ensure that evolving sustainability choices do not compromise performance, safety or lifespan.

Moving Beyond Assumption

Building on analytical insight from previous research into rubber crumb systems, the current KTP combines:

- Standard and modified on-site performance testing

- Structured data collection under real usage conditions

- Laboratory analysis of organic infill materials

- Controlled evaluation of durability properties

Organic infills exhibit more complex behaviour than SBR systems. Variations in density, porosity and moisture retention mean their response to play, weather and maintenance differs materially.

One key area of investigation is particle degradation. The research team has developed an innovative method for precisely measuring how the particle size distribution of installed organic infills changes during service life.

Monitoring degradation at this level provides insight into:

- Infill particle size range vs the rate of compaction

- Rotational rates

- Drainage issues

Given that organic infills are generally considered less durable than SBR, understanding breakdown mechanisms is fundamental to effective asset management.

Data-Driven Maintenance Evolution

Field testing forms a critical component of the project.

By systematically analysing how different maintenance techniques influence surface performance on non-SBR systems, the team can evaluate whether traditional maintenance frequencies and methodologies remain appropriate.

The collected data enables modelling of performance degradation over time, allowing Technical Surfaces to design tailored asset management strategies specific to each organic infill system.

For venue owners, this means:

- Maintenance regimes aligned to material behaviour

- Predictable performance management

- Reduced risk of premature surface failure

- Improved lifecycle planning

Sustainability Must Be Matched by Strategy

As the artificial turf industry embraces greater sustainability practices, maintenance strategy must evolve in parallel.

Organic infill systems represent an important step in environmental progression. But they are currently a high-value item, with a higher expenditure knock-on effect for playing surface running cost.

Without robust evidence-based maintenance frameworks, the intended environmental benefits could be undermined by reduced durability or increased infill costs. Something that is under constant research and review to find the ideal solution.

This partnership ensures that innovation in materials is matched by innovation in maintenance.

Because future-proofing artificial turf does not stop at installation.

It continues, year after year, through informed, data-led surface management.